Blog

What You Need to Know About Container Rain

Container Rain: A Common Problem in Maritime Shipping and Its Solutions

In maritime shipping, a frequently encountered phenomenon that causes damage to products is 'Container Rain', especially during long-duration shipments. This condition, arising from the effects of saltwater and air density, can lead to significant financial loss and damage to reputation if proper measures are not taken. In this article, we will thoroughly explore the causes, effects, and methods for preventing Container Rain.

Particularly in exports, ensuring safe and clean shipments without rust, mold, and bad odor is a major challenge for many industries. Like any tough test, it requires meticulous preparation and full equipment to overcome all conditions. Of course, with the guidance of an expert... In this context, we will focus on topics such as 'maritime shipping' and 'corrosion prevention'.

Let's take a closer look at these challenging conditions to understand them better;

Temperature Extremes During Shipment

The air temperature will fluctuate to extremes throughout the shipment. The high temperature difference between day and night is the primary cause of condensation. This remains a serious risk factor even in stable conditions. As your products journey through different climate types, over weeks or perhaps months, they are exposed to liters of water.

Let’s conduct a case study using the table below

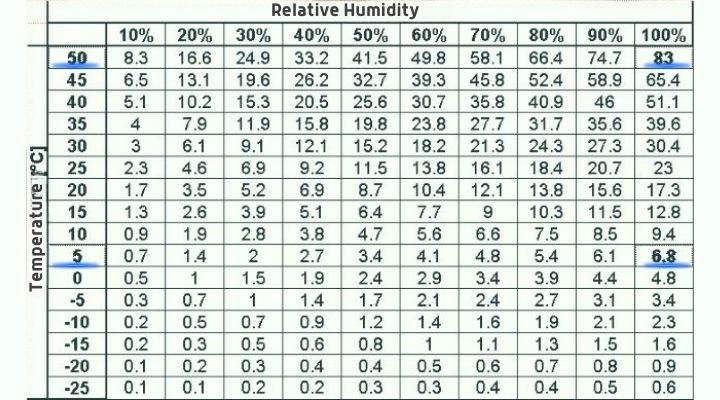

Figure 1: Air Temperature - Relative Humidity and the Variation of Moisture Content in the Air (g/m⊃3;) Table

When we examine the values in the table, we observe that the amount of moisture the air can hold decreases rapidly as the air temperature drops. The excess water vapor that cannot be held will condense rapidly on any surface it encounters, transitioning into liquid form. For instance, during the day, the air inside a container exposed to 50°C can hold 83g/m⊃3; of water vapor per cubic meter. At night, if the air temperature suddenly drops to 5°C, the amount of moisture that can be carried in 1 m⊃3; of air decreases to 6.8g/m⊃3;. The difference of 76.2g/m⊃3; of moisture will then condense entirely on your products. Considering that the volume of containers in industrial shipments is much greater than 1 m⊃3;, the magnitude of the risk is evidently significant.

Highest Risk Category: Overseas Shipments

The general principle of condensation inside containers is as described. But, is every environment in the same risk category? No. Generally, humid climates pose a greater risk, but there's a situation that requires careful attention and awareness: MARITIME SHIPPING.

In coastal climates, the air holds excessive moisture. This humidity is why we sometimes struggle to breathe on hot days in certain regions. Similarly, during overseas journeys, the amount of moisture in the air inside the container is quite high. The temperature change at night will cause a significant amount of this moisture to condense and turn into liquid. Unfortunately, this is not the only danger present in such environments. The salt in the environment is one of the factors that contribute to corrosion.

On metal surfaces, some areas are more 'active' than others, attracting electrons. The weaker sections release electrons, becoming positive ions and dissolving, while negative ions, due to ionic attraction forces, rush towards the corrosion area. This process accelerates the dissolution of the metal, consequently speeding up corrosion. Erosion then begins in the direction of gravity.

Can We Eliminate Container Rain with Just One Product?

In international shipments using containers, especially in high-humidity maritime environments, the significant temperature difference between day and night causes the moisture in the air inside the container to contaminate, leading to the phenomenon known as 'Container Rain.' This event adversely affects both the packaging and the quality of your product inside the container.

These specially formulated CONTPACK PLUS packets, available in various sizes ranging from 250 grams to 2 kilograms, work continuously for 60–80 days, preventing moisture condensation and can adsorb up to 100% of their weight in water and moisture. They are highly recommended for ensuring the safe transit of all your shipments and preventing your products from reaching your customers with moisture damage.

FEATURES

- Provides highly efficient protection against the detrimental effects of moisture, directly impacting the quality of your products during shipping or storage.

- Effectively prevents container rain caused by the condensation of moisture due to day and night temperature differences.

- With high adsorption performance, it works continuously for 60–80 days, ensuring maximum efficiency.

- Absorbs excess moisture left inside the container from materials like cardboard boxes, pallets, etc., thereby preventing all sorts of external humidity and odor issues.

- Creates a dry and healthy shipping environment, not only protecting your products but also instilling a strong sense of trust in your customers.