Blog

Silica Gel Types, Advantages, and Disadvantages: A Comprehensive Guide

What is Silica Gel?

Silica Gel is an effective desiccant primarily used in the metal processing sectors, among others, for moisture control during packaging processes. These special desiccants have the capacity to rapidly adsorb moisture from the air trapped inside the packaging within 48-72 hours. Thus, silica gel is among the synthetic desiccants ideal for sensitive applications, creating significant effects in small volumes.

Key Considerations in Using Silica Gel

Silica gel is widely preferred across a broad spectrum of industries, from automotive to defense, aviation, and machinery manufacturing. There are critical points to ensure the effective use of desiccants:

- Determining the Correct Amount: It's essential that the amount of silica gel used is proportional to the volume of air within the package.

- Even Distribution: For instance, if there's a need for 500 grams of desiccant, dividing this amount into equal portions (e.g., 2x250 grams or 5x100 grams) and distributing it evenly inside the packaging ensures more effective moisture adsorption.

- Prevent Moisture Absorption Before Use: Ensure that silica gel packets have minimal contact with air before use to prevent them from absorbing moisture prematurely.

SILENT ALARM: Indicator Silica Gels

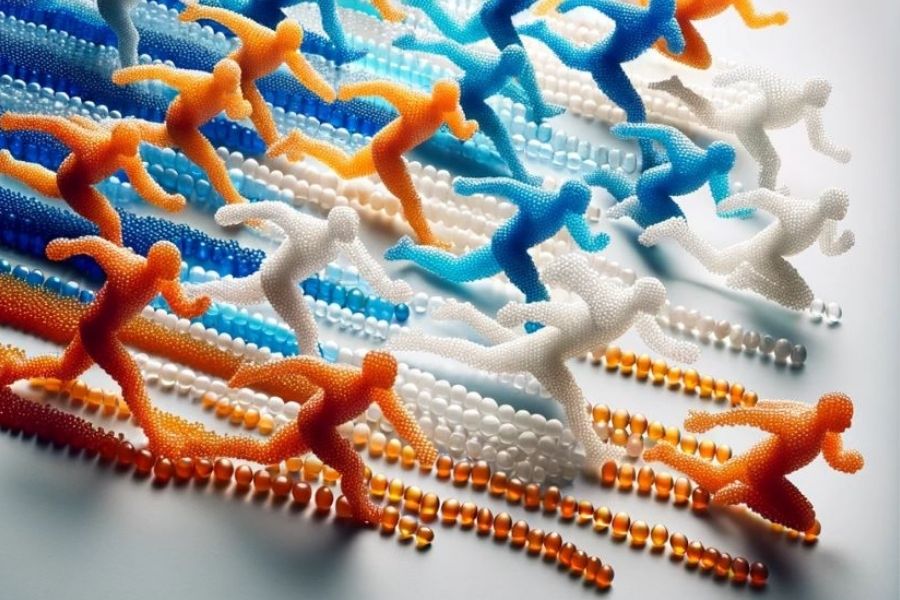

Silica gels are utilized in packaging in various weights. Similar to all desiccants, the packaging process for white silica gel packets should be completed in a manner that minimizes air contact. However, tracking the exposure time of silica gels to open air during extended stops and shift changes can be nearly impossible. This creates a need to visually monitor the amount of moisture absorbed by the silica gel. Here, indicator silica gels, which change color upon absorbing moisture, come into play. Indicator silica gels available in orange and blue options warn the applicator by turning transparent, green, or pink as they absorb moisture.

Choosing Indicator Silica Gel: Key Points

While there is no fundamental performance difference between orange and blue indicator silica gels, the blue silica gel's cobalt content may make it less preferable for certain sectors. At Desi Chemicals, we recommend updating your existing white silica gel habits to include orange-white or blue-white options, ensuring maximum efficiency from your desiccants. We advise consulting with a Desi Specialist for more information and tailored solutions.