Blog

IS VCI PACKAGING SUFFICIENT FOR EVERY APPLICATION?

In overseas shipments, you chose VCI packaging. But is VCI packaging alone sufficient for protection in every application?

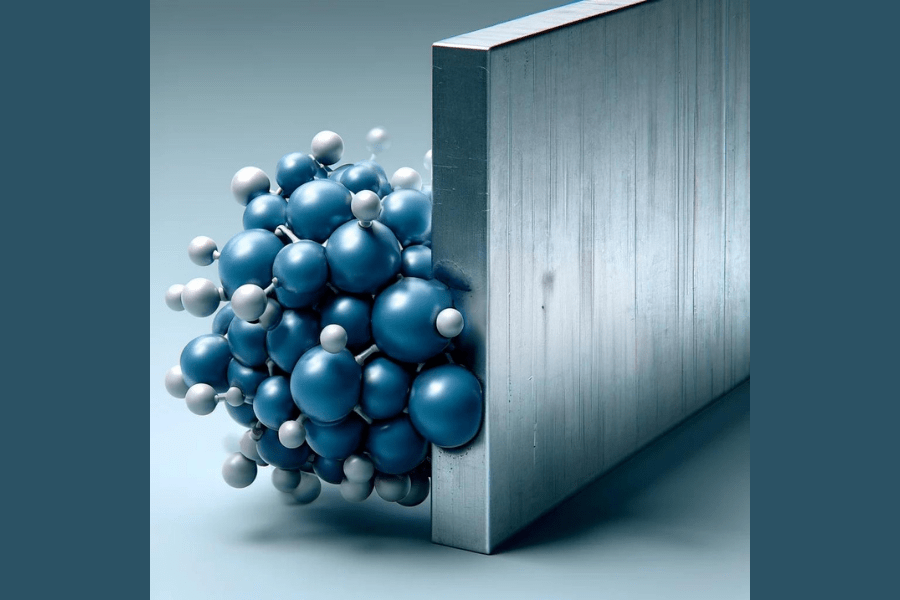

The VCI molecules in your packaging vaporize and then form a protective barrier on the metal surface. However, for this process to be successfully completed, the VCI molecules must reach the metal surface.

What situations can prevent VCI molecules from reaching the surface?

-

Large-volume, highly porous products: If you consider that the packaging only touches the outermost surface of your product, there are certain risk points in your large-volume and porous products. These risk points are the surfaces farthest from the packaging. Here, the concentration of VCI needs to be quickly increased. Otherwise, the necessary VCI concentration for high protection may not be achieved. You might need to use VCI emitters such as VCI tablets, VCI+DRY (which can also hold a high amount of moisture), etc. Thus, the VCI ratio inside the packaging surrounding your product increases rapidly, ensuring full protection even at the farthest points.

-

Stacking that may create barriers: Anything that prevents VCI molecules from reaching the metal surface creates a risk point. This includes your own products. In stacked arrangements, there might be a situation where metal parts block each other. To overcome this negative effect, it is necessary to use separators containing VCI. VCI-containing PP Sheets, VCI cardboard might be ideal for your application. Thus, you ensure that VCI reaches all surfaces of your products on each level, and you also prevent physical deformations that could occur due to friction.

-

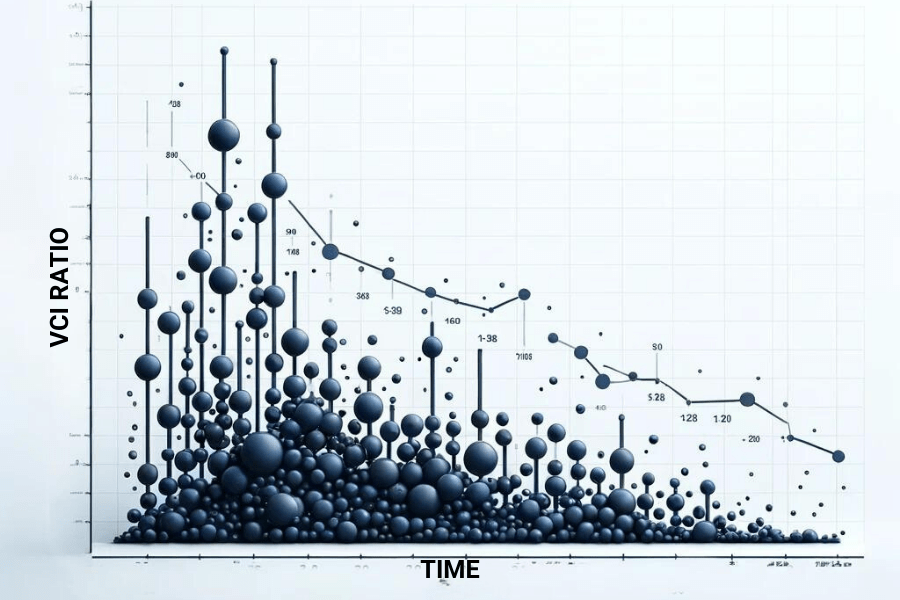

Long storage periods: Your VCI packaging application may be sufficient during shipment time. But have you considered long storage periods?

It is necessary to be aware of and plan for the duration your customer intends to store the products, which might be known and included in the planning. This period could be as short as 6 months or as long as 10 years. The longer the period, the more the amount of VCI molecules inside the packaging will decrease. Therefore, when long storage periods are considered, you will need to use Aluminum VCI Packaging with almost zero air and UV permeability. In addition, supporting the system with Sil-Pack packaging would be beneficial.

Overseas shipments and long storage periods should be analyzed within their own contexts. For information on the most suitable products and methods for your processes, you can consult a DESI expert.