Blog

For Those New to Technology, "What Exactly is VCI?

What Exactly is VCI?

VCI stands for Volatile Corrosion Inhibitor. Thanks to this technology, which only a few manufacturers worldwide possess formulations for, your metal products are fully protected from corrosion during overseas shipments and long storage periods.

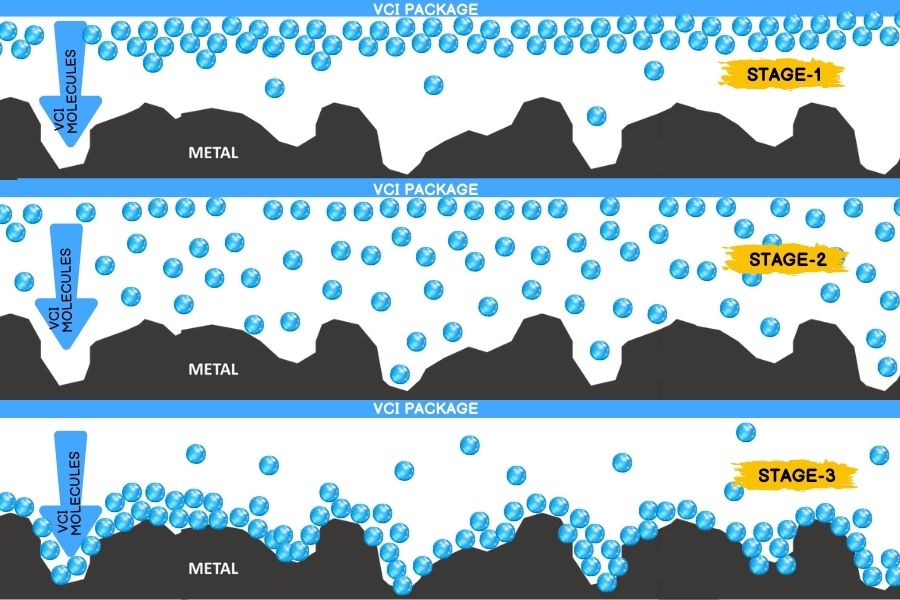

The most common application is the use of packaging containing VCI. Metal products are wrapped in VCI packaging in an airtight manner. The VCI molecules inside the package transition to vapor phase, moving towards the metal surface and creating a dense VCI vapor. Subsequently, a micro-thin protective layer of VCI forms on the metal surface. Thus, the metal surface is protected against corrosion for as long as it remains inside the packaging.

What are the Applications of VCI?

While the most common application involves packaging containing VCI (PE, paper, aluminum, etc.);

- VCI Emitters: This category includes products in the form of tablets, capsules, and those that absorb moisture and emit VCI. They play a supportive role in protecting electronic systems, products with large volumes, or complex geometries.

- VCI Powder: Predominantly used in the pipe industry, these are concentrated powder products applied to the surface by spraying.

- VCI Separators: Developed to protect each layer from corrosion and physical deformation in dense and stacked arrangements.

- Metal Process Chemicals: There is a VCI version for many process chemicals. These product groups not only protect the surface for a much longer period but also help remove invisible corrosion from the system during inter-process periods.

- VCI Spray: While protecting the surface against corrosion, it also supports the appearance of the finished surface. It is ideal primarily for the machinery and mold industry. There are also VCI oils among different application methods.

Are All VCI Formulations the Same?

VCI formulation can vary from manufacturer to manufacturer. Therefore, certain criteria should be considered when procuring VCI products.

- Does your VCI packaging provide GRADE-3 level protection? Always request a VCI Effectiveness Analysis conducted by independent organizations.

- Eliminate heavy metals and chemicals harmful to human health from your system! There can be many VCI formulations. Some of these may contain heavy metals and harmful chemicals. Also, when choosing a VCI product, confirm with reports that it has a “Nitrite Free” content. (You can examine the relevant standard TRGS 615)

For more detailed information about VCI products, you can seek help from a DESI expert.